HMI Design for Machines and Technical Devices

In today’s manufacturing environments, Human-Machine Interfaces (HMIs) are essential for the efficient and user-friendly operation of machinery and equipment. Well-designed HMIs enable operators to perform their tasks quickly, intuitively, and with minimal risk of error. At CaderaDesign, we develop tailored HMI solutions that meet your specific requirements and the needs of your users. We'd like to share what we believe defines successful HMI design in industrial settings – and what you should pay special attention to.

What makes a good HMI design?

"An HMI should be perfectly aligned with the operator and their working environment. The HMI panel must be ergonomically positioned and the user interface should be intuitive. The design should guide the user’s attention positively, enabling them to complete their tasks efficiently and with satisfaction. A strong user experience – through a well-structured user journey – is key."

Florian Fuchs, CaderaDesign

User-centred interface design: Understanding and implementing user needs

Designing a human-machine interface means adapting it to the needs and abilities of the user. This includes aspects such as ergonomics, cognitive science and psychology. Key information must be presented clearly and with focus, while controls must meet user expectations.

Ergonomic HMI design: Enhancing human-system interaction

HMIs are embraced by users when the operation feels logical and transparent. For interfaces to be efficient, effective and satisfying to use and learn, relevant standards such as DIN EN ISO 9241 (Ergonomics of human-system interaction) must be considered.

Interactive concepts for human-machine interfaces: Optimise the user experience

Well-designed interaction concepts empower users to complete their tasks efficiently and intuitively understand process contexts. Clear navigation and well-marked interactive controls are essential for improving the user experience. Real-time visualisations and animations further support user comprehension.

Guiding attention for focused interaction

To increase operational efficiency, users’ attention must be directed towards the right information. In critical production environments, error messages and system alerts need to be clearly structured and easily recognisable – to optimise response time and reduce cognitive load.

Modular HMI design: Flexibility and efficiency for machine control

Modularity is a core principle in HMI design. It applies not only to the visual and product design, but also to the underlying software architecture. With reusable design patterns, we implement software applications quickly and efficiently.

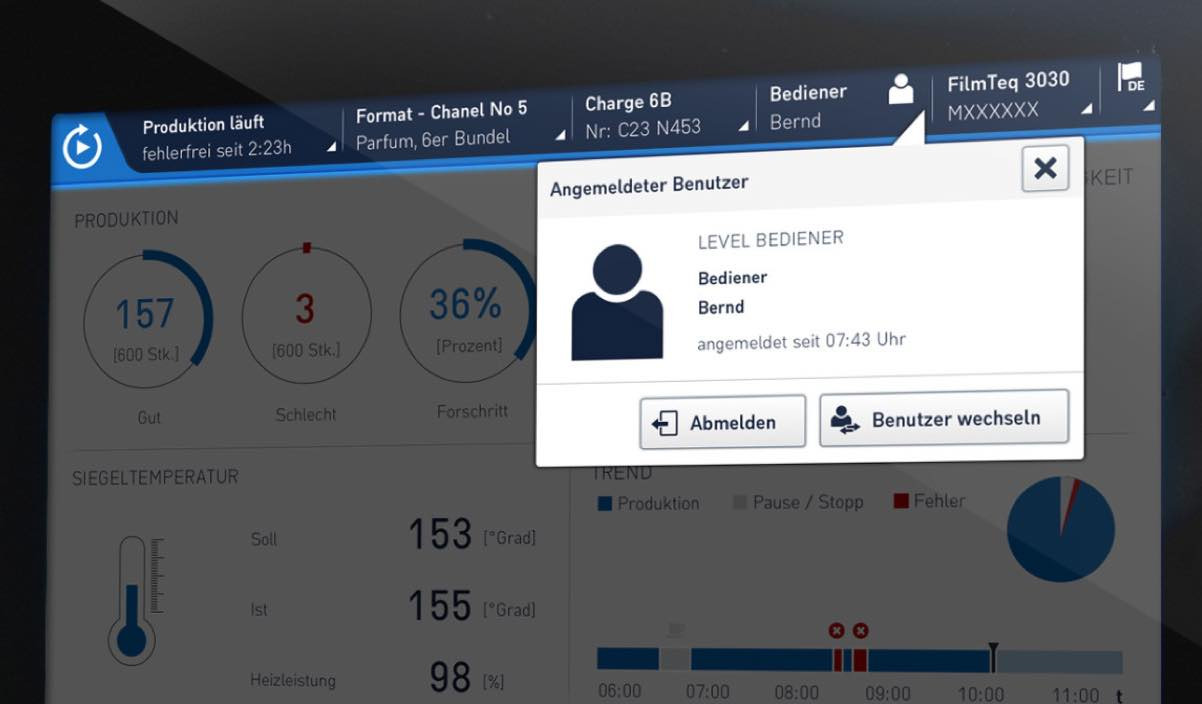

User roles and security in HMI design

For safe operation, it is crucial that user roles such as operator, administrator, or service technician are clearly defined. This ensures each group only accesses the information relevant to their tasks, increasing overall safety and reducing errors. Login methods – whether via password, RFID cards, facial recognition or fingerprint sensors – must be chosen accordingly. This forms the basis for designing interfaces and screens tailored to real-life usage scenarios.

Optimising HMI panels and hardware: Ergonomics and interaction

Choosing the right hardware is a crucial aspect of HMI design. How will users interact with the device? At what height and in what position should it be mounted? Should the operator be mobile or work hands-free? These considerations directly affect the choice of devices. Will hardware buttons or emergency stop switches be integrated physically, or via software? These questions must be answered to ensure intuitive and efficient user interaction – while also accounting for economic and technical factors.

User Interface Design at CaderaDesign: From Machines to IoT Platforms

At CaderaDesign, we go beyond traditional machine HMIs – we design all types of user interfaces for devices, machinery, systems and technical equipment. This includes mobile devices and IoT platforms. Our design concepts streamline operations, enhance user experience and increase your system’s ROI. With better usability, you also benefit economically while strengthening your brand.

Key benefits of a well-designed HMI

- Boost perceived quality and visual appeal

- Enhance your brand image and create desirability

- Improve customer loyalty through positive user experience

- Maximise usability for greater efficiency and reduced costs

- Reduce operator errors and increase overall productivity

Your contact for your HMI design project

Florian Fuchs

- UX & Usability Engineering

- User Interface Design

fuchs bei caderadesign punkt de

HMI design in practice - our references at a glance

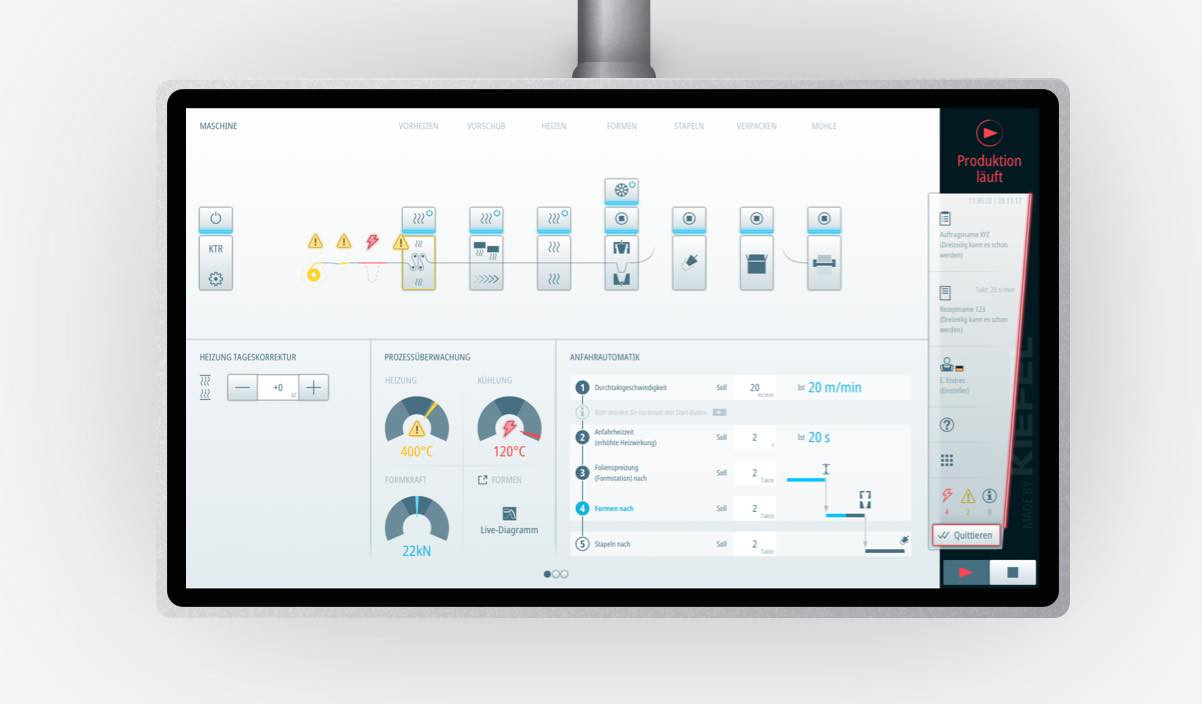

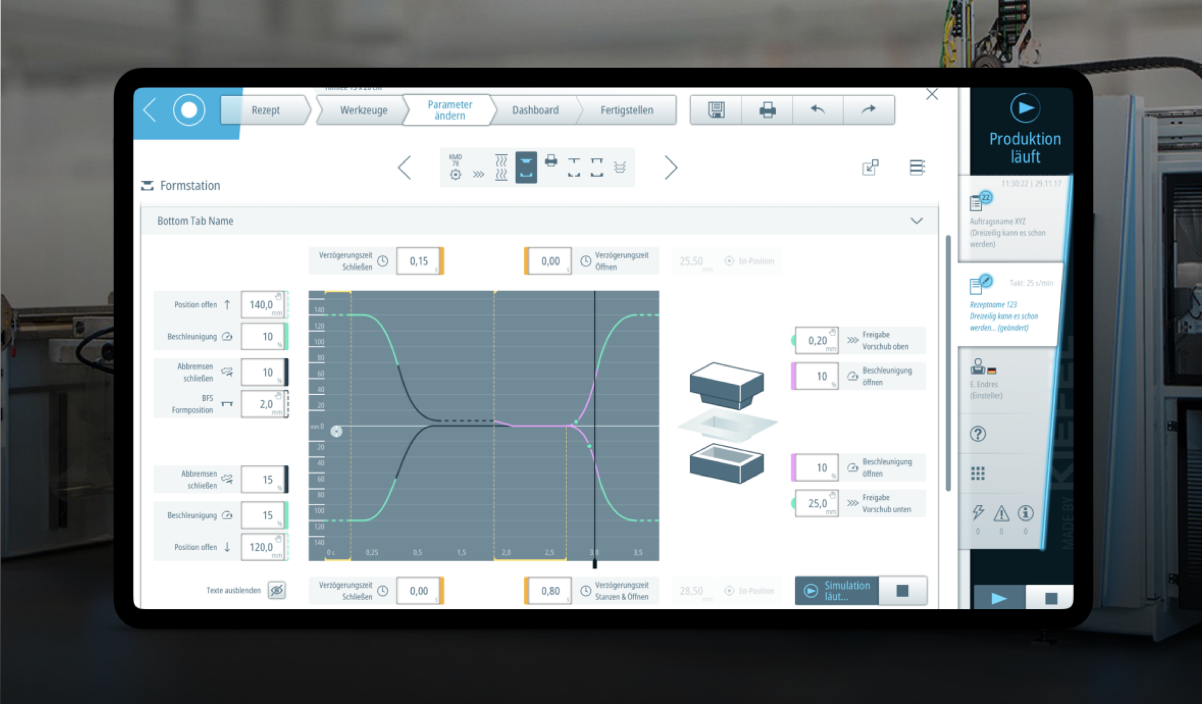

Kiefel | HMI

HMI for packaging machines

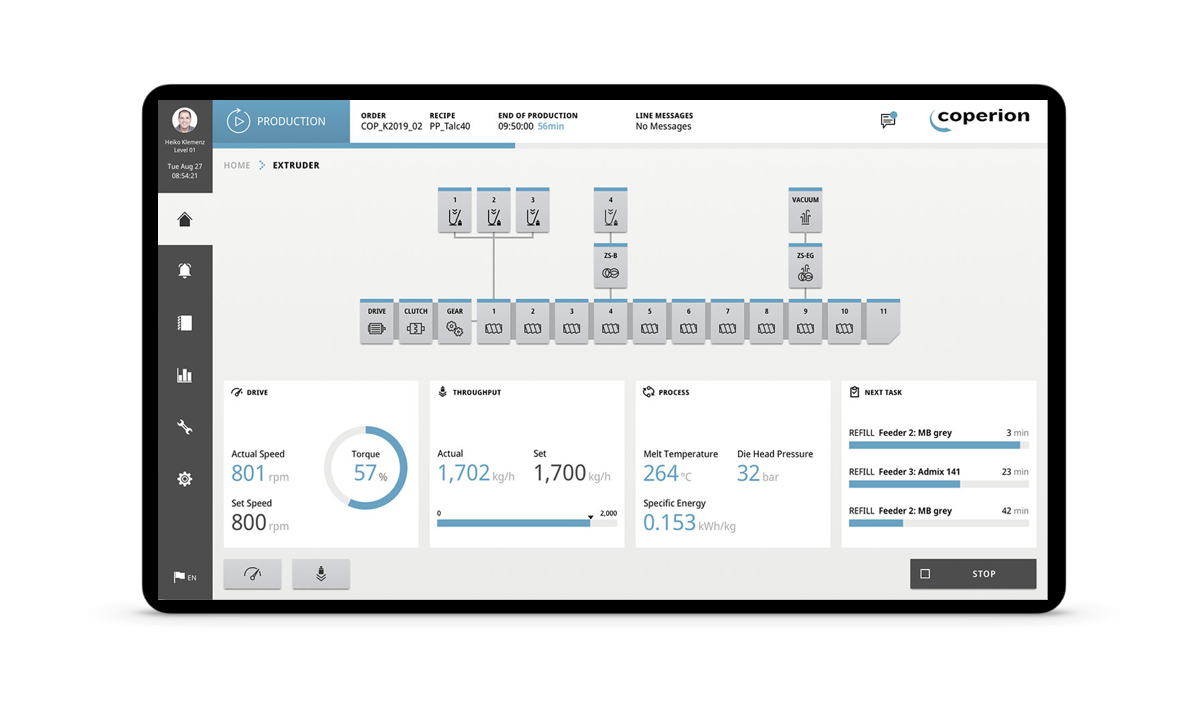

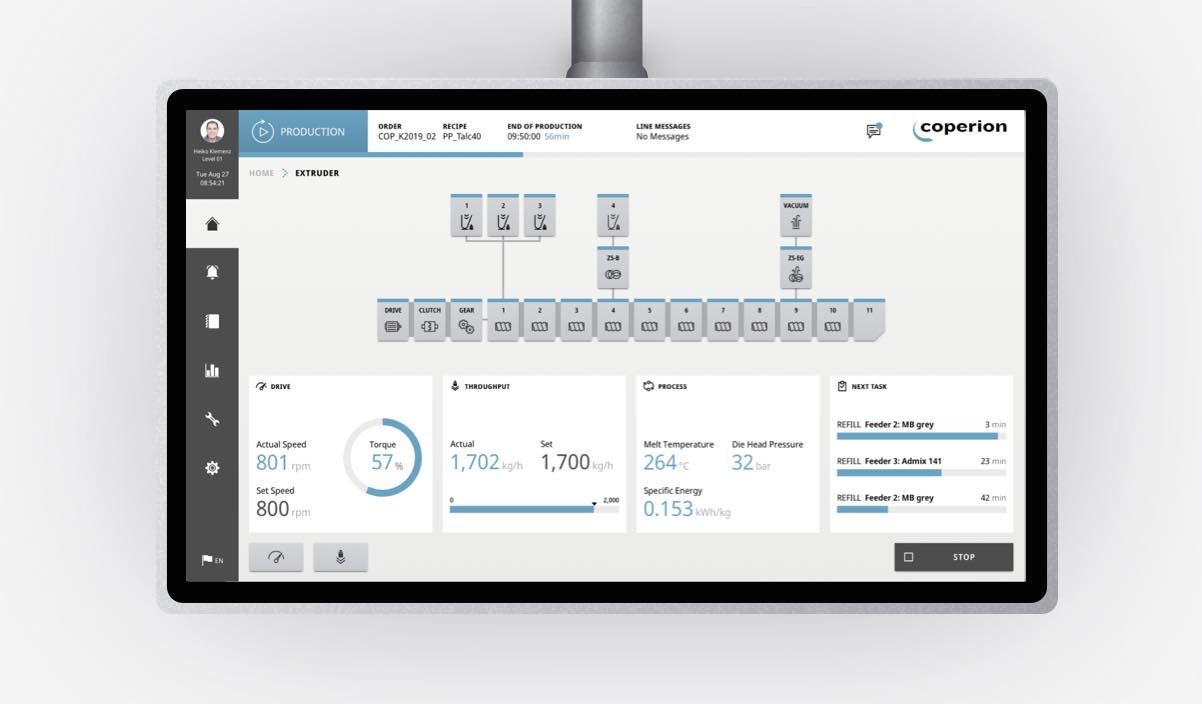

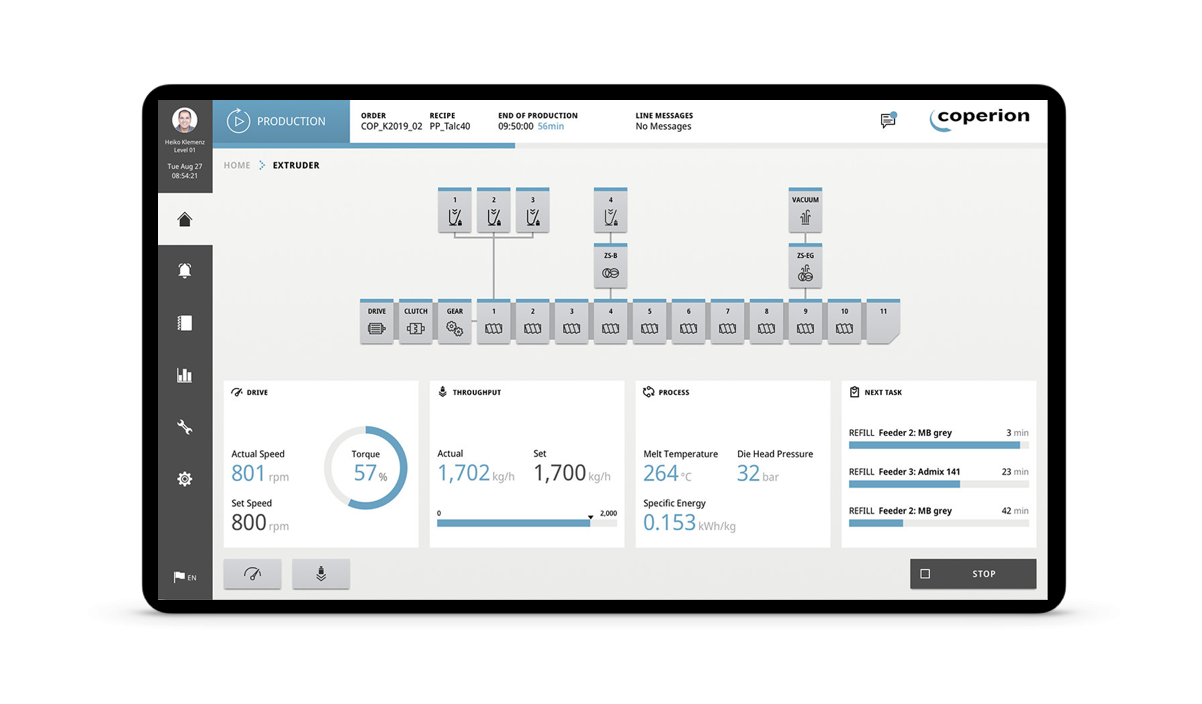

Coperion | C-Beyond HMI

HMI for extrusion lines

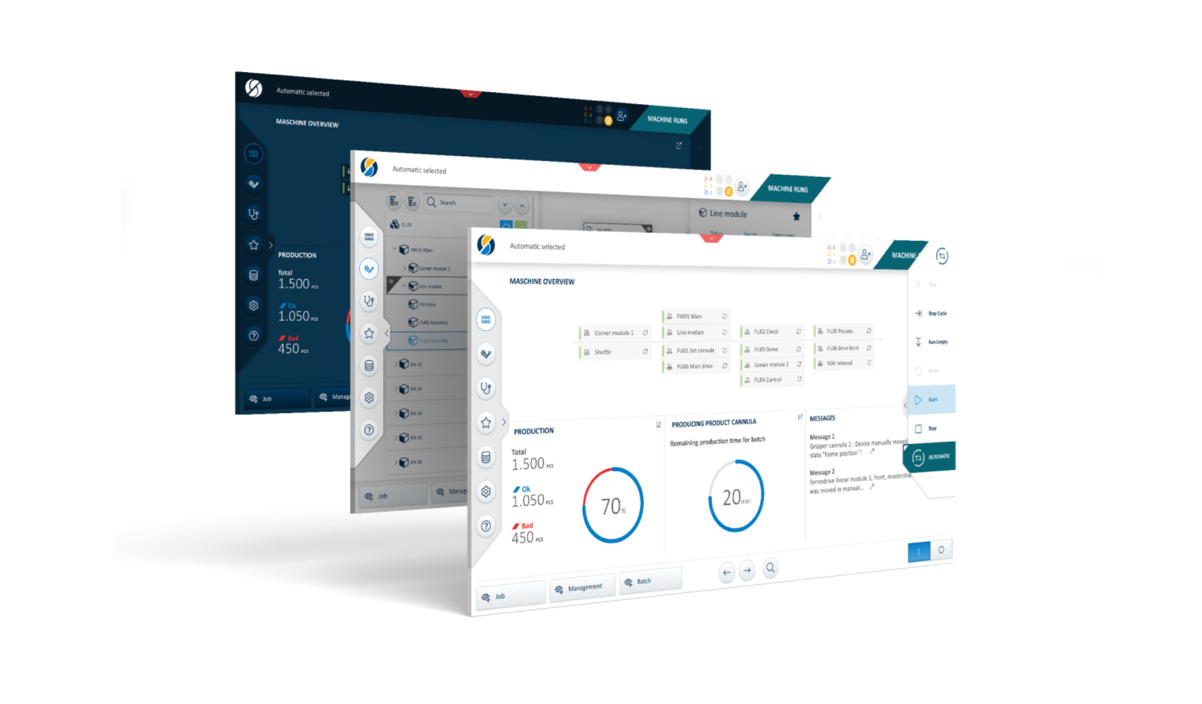

Strama-MPS | MyHMI

HMI for special machines

Uhlmann | Pexcite

Pharma packaging platform

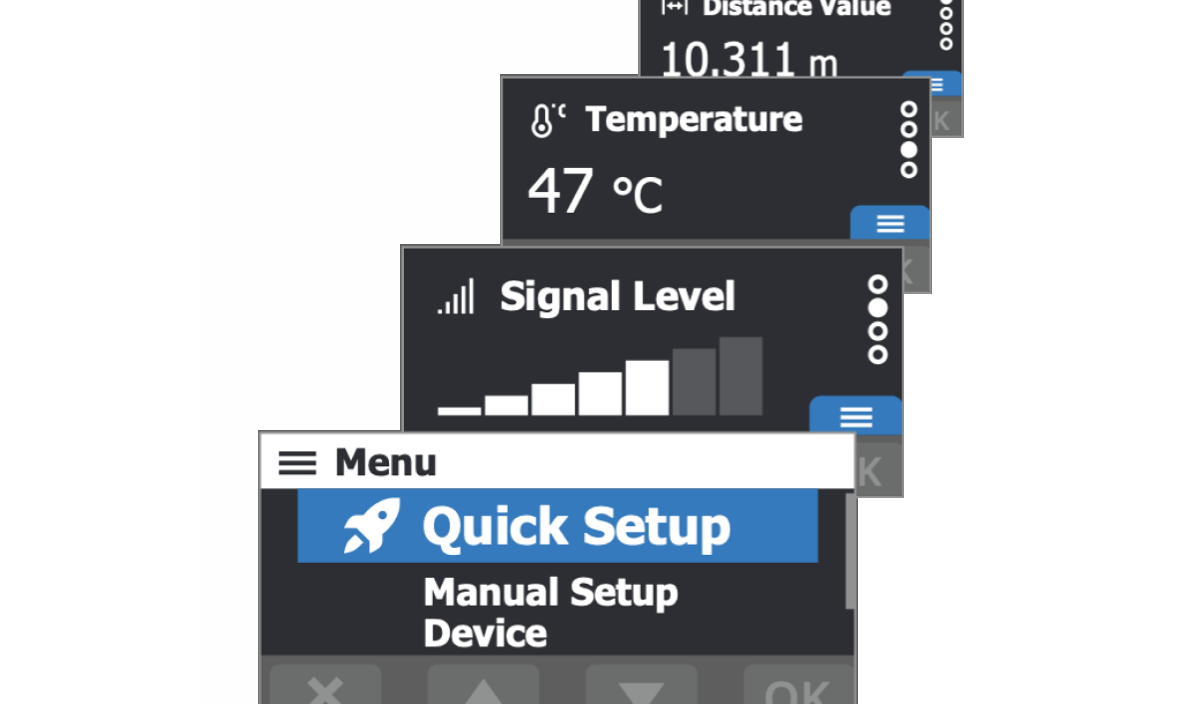

Sick | measuring device

HMI for measurement systems

Miwe | MIWE Go!

Oven control

Qube Munich | Terminal

HMI for robotics caterer

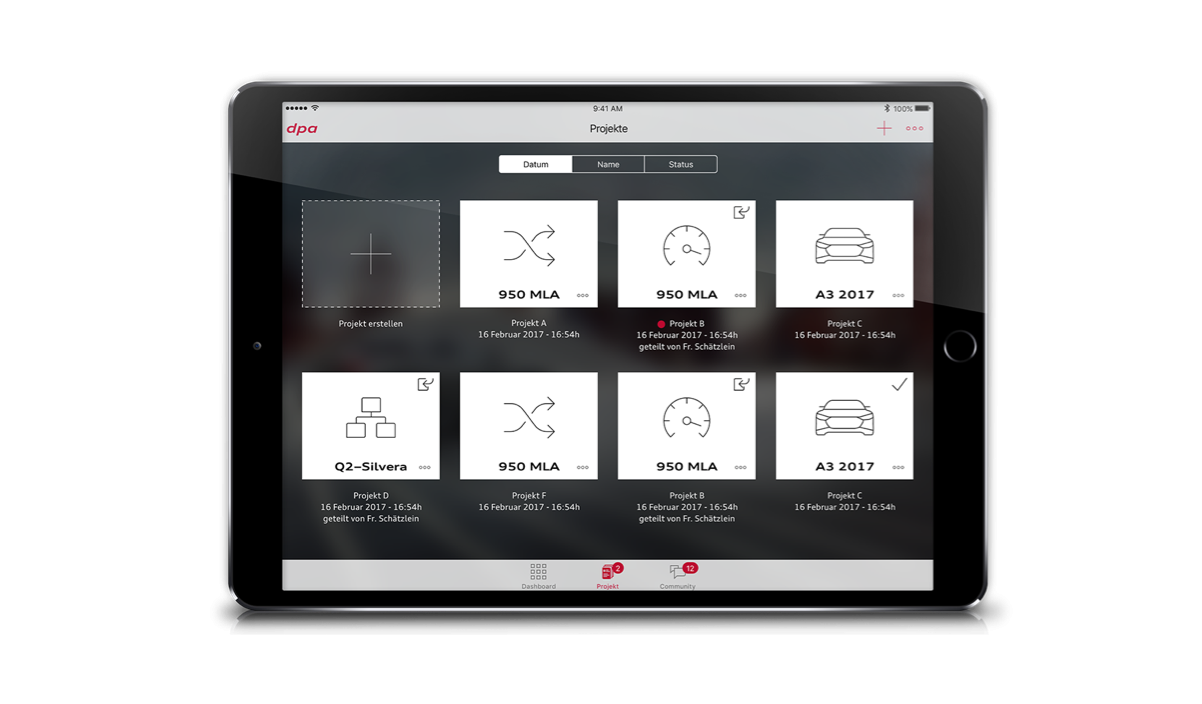

Audi | dpa

Digital planning assistant

Koch | easyControl

HMI for packaging machines

Harro Höfliger | HMI

HMI for packaging machines

Christ | HMI

HMI for packaging machines

bdtronic | mini-dis

HMI design for dosing systems

Key HMI Terms Explained: Everything You Need to Know About User Interfaces

HMI

The term HMI, short for Human-Machine Interface, is often used colloquially to describe a specific hardware-software combination for operating machinery or devices. In a broader sense, however, it refers to any user interface (UI) that acts as a bridge between human and technology. Whenever someone interacts with a technical system in any way, an HMI is involved. Traditional examples of user interfaces include buttons, switches or indicator lights. Today, when we speak of user interfaces or human-machine interfaces, the range of possible forms such an interface can take is far more diverse.

Graphical User Interfaces (GUIs)

In the past, machines were operated using hardware buttons (hard keys). With advances in software, graphical user interfaces (GUIs) were introduced. GUIs visualise controls and allow for flexible content display. In industrial settings, GUIs were initially operated via soft keys, then with trackpads and keyboards. Today, touchscreen operation is widespread. Tasks such as machine operation, setup and maintenance are typically performed via touch panels. For setup and servicing, remote solutions are also available, displayed on PC monitors and controlled with mouse and keyboard. Mobile devices such as tablets and smartwatches are increasingly being used in production environments for a variety of tasks (see IIoT and shopfloor). Head-mounted displays, such as virtual reality (VR) or augmented reality (AR) glasses, are being developed for remote service and training scenarios.

User

Anyone operating an HMI usually does so with a specific goal in mind: they want to complete a task or solve a problem. For this reason, terms such as user, operator or end-user are often used interchangeably.

Software ergonomics

Software ergonomics (also known as usability engineering, a subfield of human-computer interaction) is concerned with designing software that is easy to understand and efficient to use.

Interactions

Nowadays, input methods exist that address nearly all human senses – from gesture-based systems to voice and eye-tracking technologies. Many user interfaces combine different interaction modes – for example, a smartphone might offer both touchscreen and voice control. The overall experience a person has while using a system – known as the user experience (UX) – should be considered independently of the underlying technology.