Industrial Design Glossar

Industrial Design

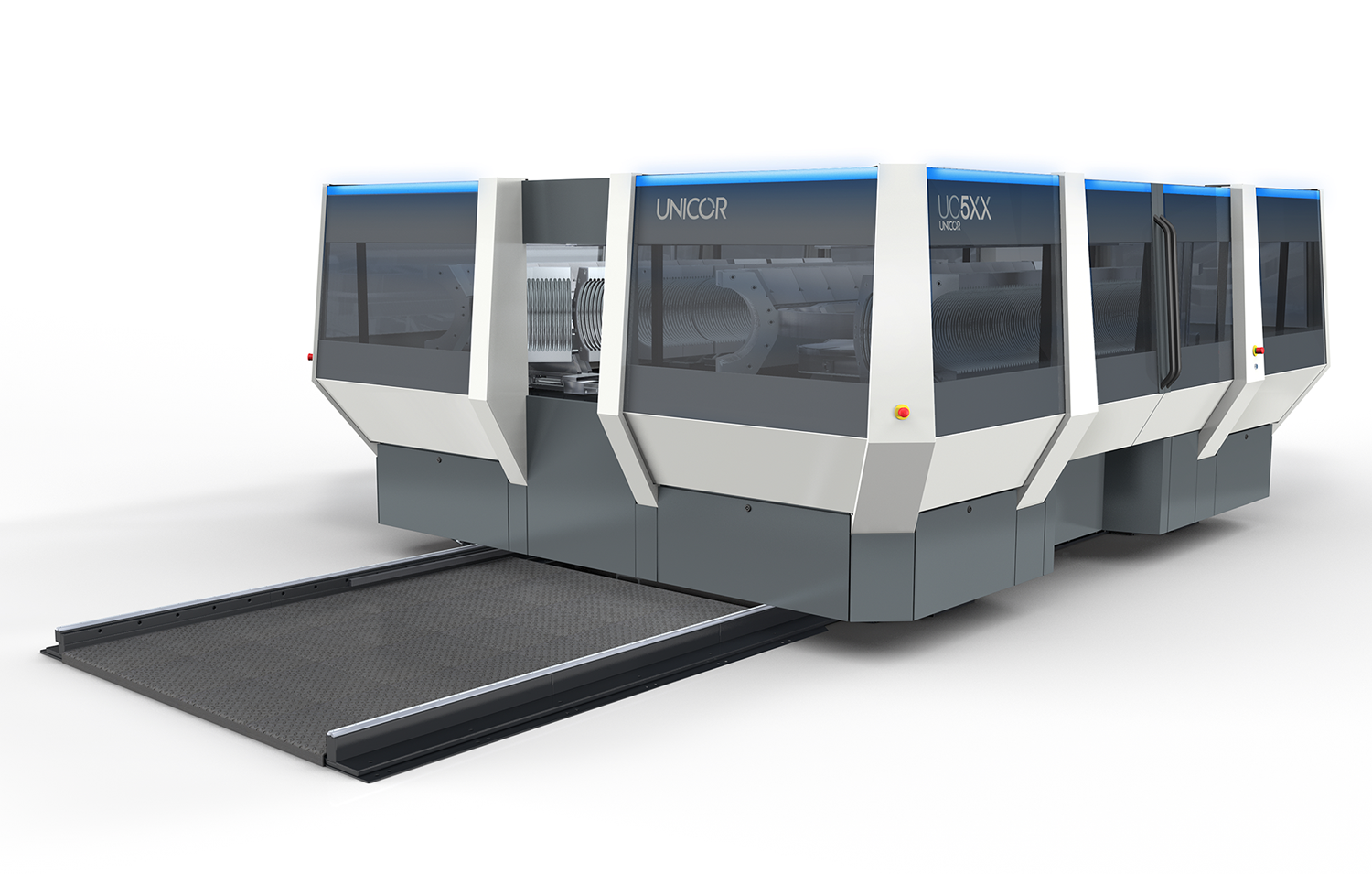

Industrial design, also called industrial design or product design (alternative spelling: product design), refers to the conception and design of industrially manufactured series products in the consumer or capital goods sector. Industrial designers enrich product development with their creative thinking and technical understanding. They bring products to life and ensure their visual, model-like or constructive implementation. Customers benefit from their ideas in different areas, e.g. when it comes to economical manufacturing processes.

In addition to attractive design, a well thought-out industrial design optimises ergonomics and user-friendliness. Customers understand the use of a product faster and are more satisfied. This creates a positive feeling and an emotional connection to a product. Industrial design is able to bring out product features and improve them. Often, the integration of innovative functions is also encouraged. For this purpose, industrial designers analyse the needs and requirements of users along the entire customer experience. It thus covers essential touchpoints of the so-called customer experience. A well thought-out industrial design also supports the brand identity and provides differentiating features to stand out from the competition. This can increase brand perception and customer loyalty and ultimately the success of the product.

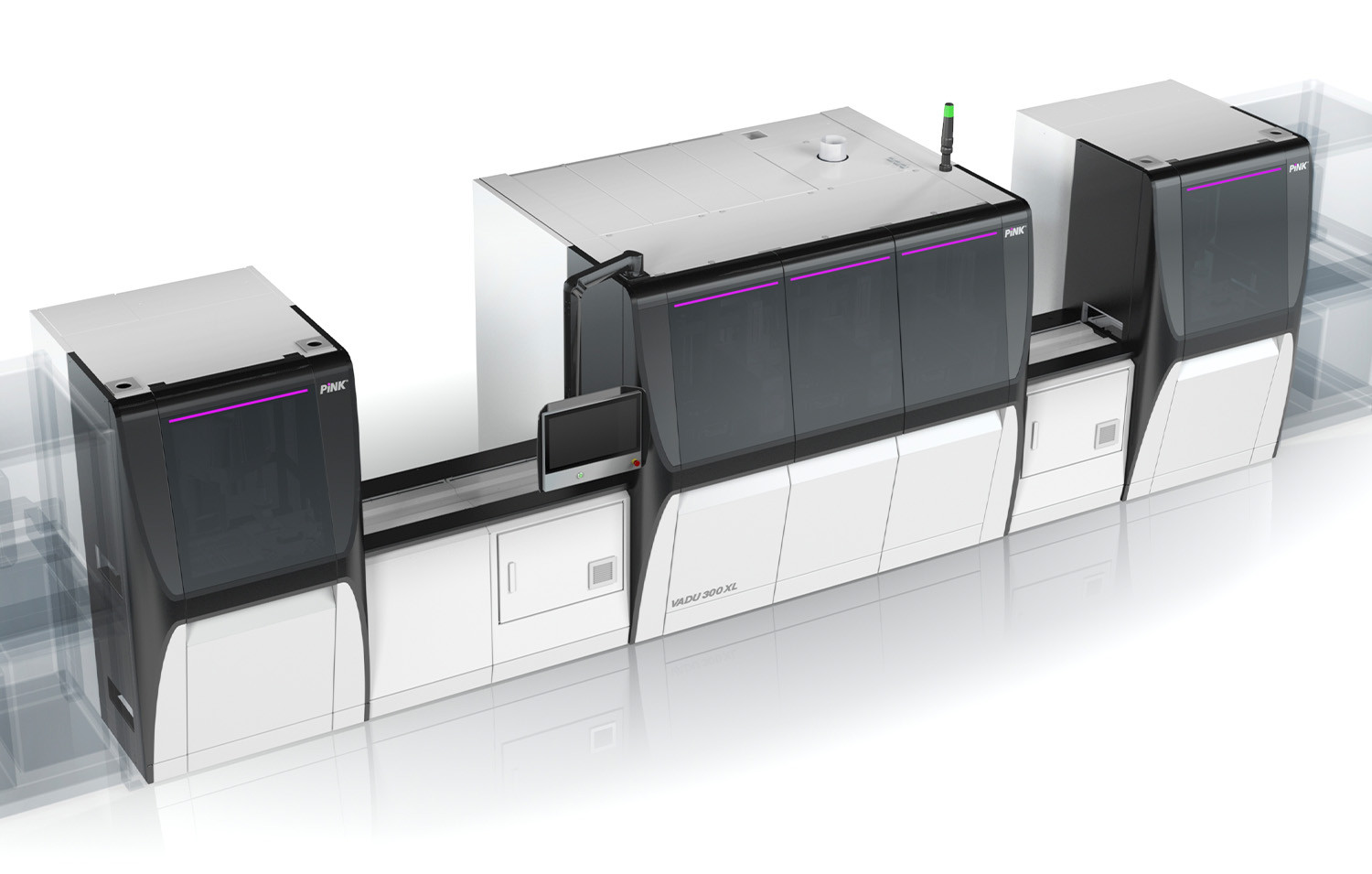

Industrial User Experience

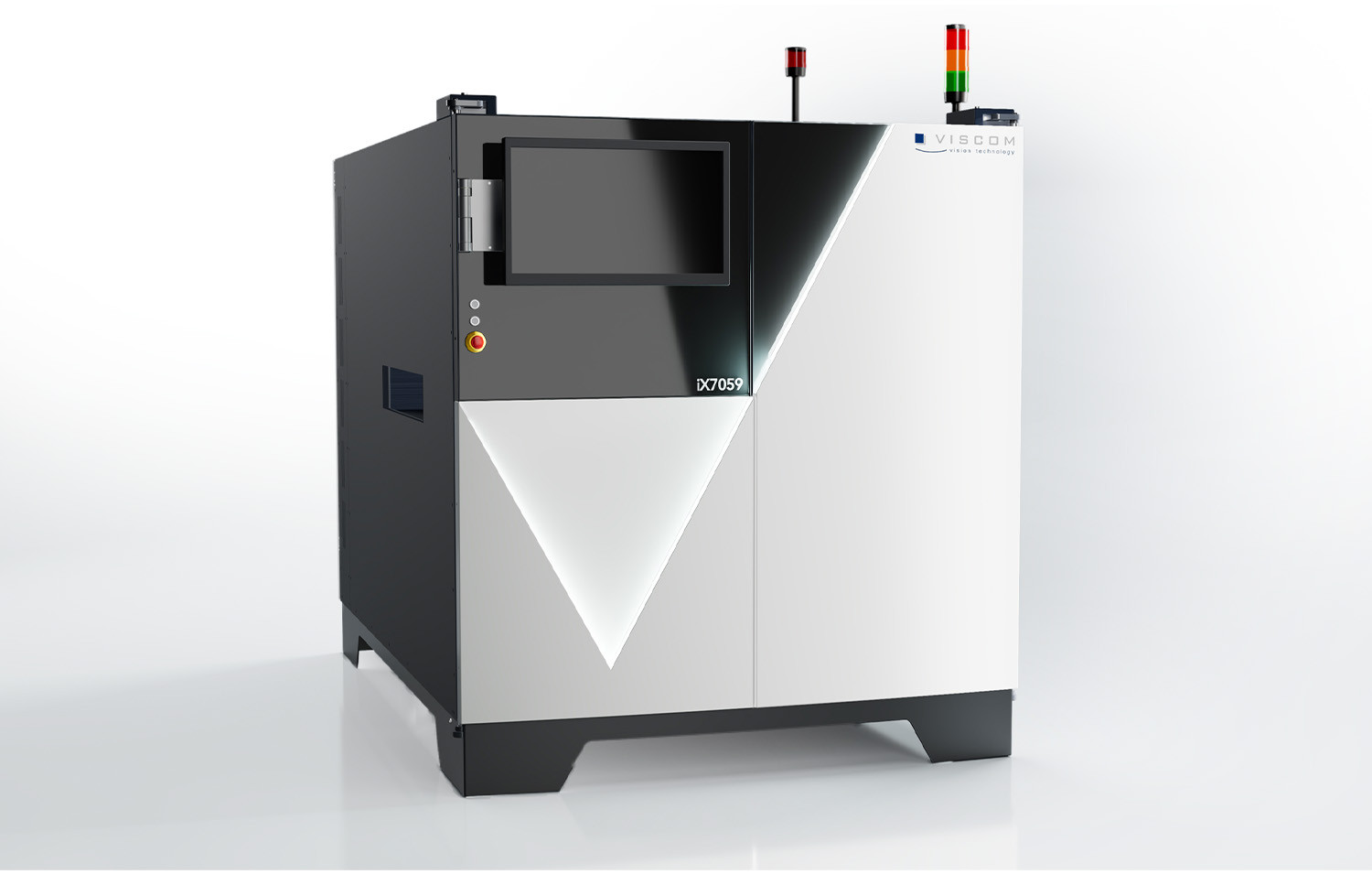

The Industrial User Experience aims to support users of machines or technical aids effectively and efficiently in their tasks. Designers analyse the needs, abilities and expectations of users in industrial environments. They use the findings for operating concepts and support the product development process. Aspects such as safety, reliability and usability must be taken into account. A positive industrial user experience can help to increase productivity and reduce the error rate, for example.

The term Industrial User Experience is currently mainly used in the context of User Interfaces or Ul-Design. We would also like to emphasise the role of industrial design and interaction with the "hardware". Such interactions are important touchpoints for the users of products and machines. Operating elements and doors and flaps that open should be tailored to each other and to the user's work. Only then can complete work processes and operator ergonomics be comprehensively optimised. One achieves a harmonious overall experience of a product, all aspects of the user experience, including usability, ergonomics, design and intuitive operation.

An overarching good Overall User Experience is perceived by people in their interaction with products - consciously or unconsciously - and in any case also experienced emotionally. This experience knows no boundaries between hardware and software. A division into user interface design and industrial design therefore makes little sense. We recommend a holistic view and approach. This is the only way to guarantee a comprehensive user experience with all touchpoints on the product and make an important contribution to a good user journey.

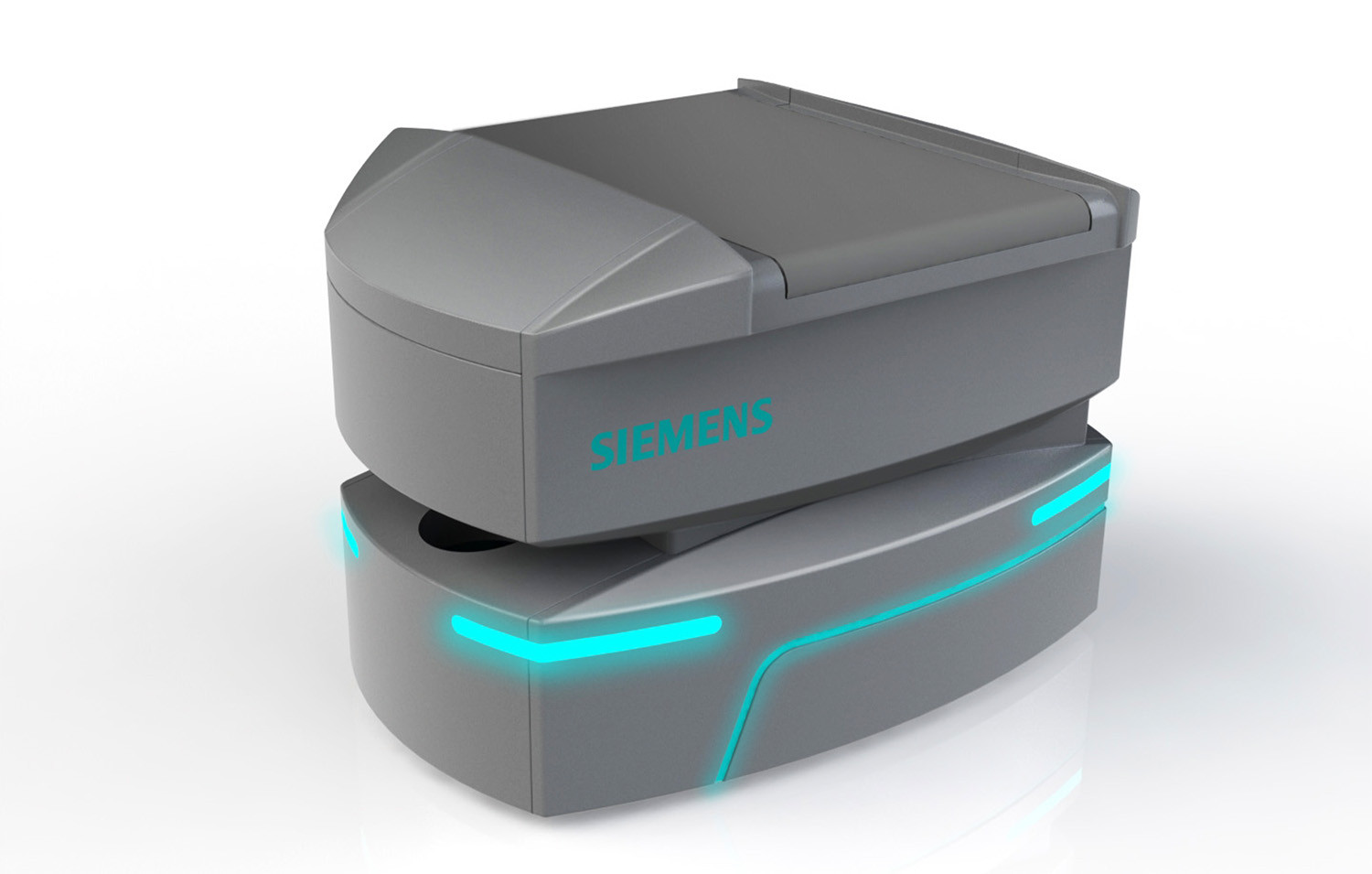

Ergonomics

Ergonomics is a human-related design discipline and sub-discipline of occupational science. It takes into account the physical and mental conditions of humans and defines them on the basis of standards and sets of rules. In man-machine action, it serves as a conceptual framework for work processes. The discipline has a major impact on the health and well-being of users. Industrial designers minimise ergonomic risks, reduce the strain of using products. This is because they analyse and take into account effects on posture, the musculoskeletal system and general health.

Ergonomic work environments and tools increase efficiency when tasks are performed. Work processes as a whole can be optimised and productivity increased. Ergonomic design optimises safety aspects and helps to avoid accidents, operating errors or injuries, e.g. by using ergonomic handles and placing operating elements well.

Cognitive ergonomics and usability are disciplines that have developed out of the ergonomics approach of industrial design. They are the logical continuation of the ergonomic idea of products on the software level and also have maximum usability as their goal.

The product design process

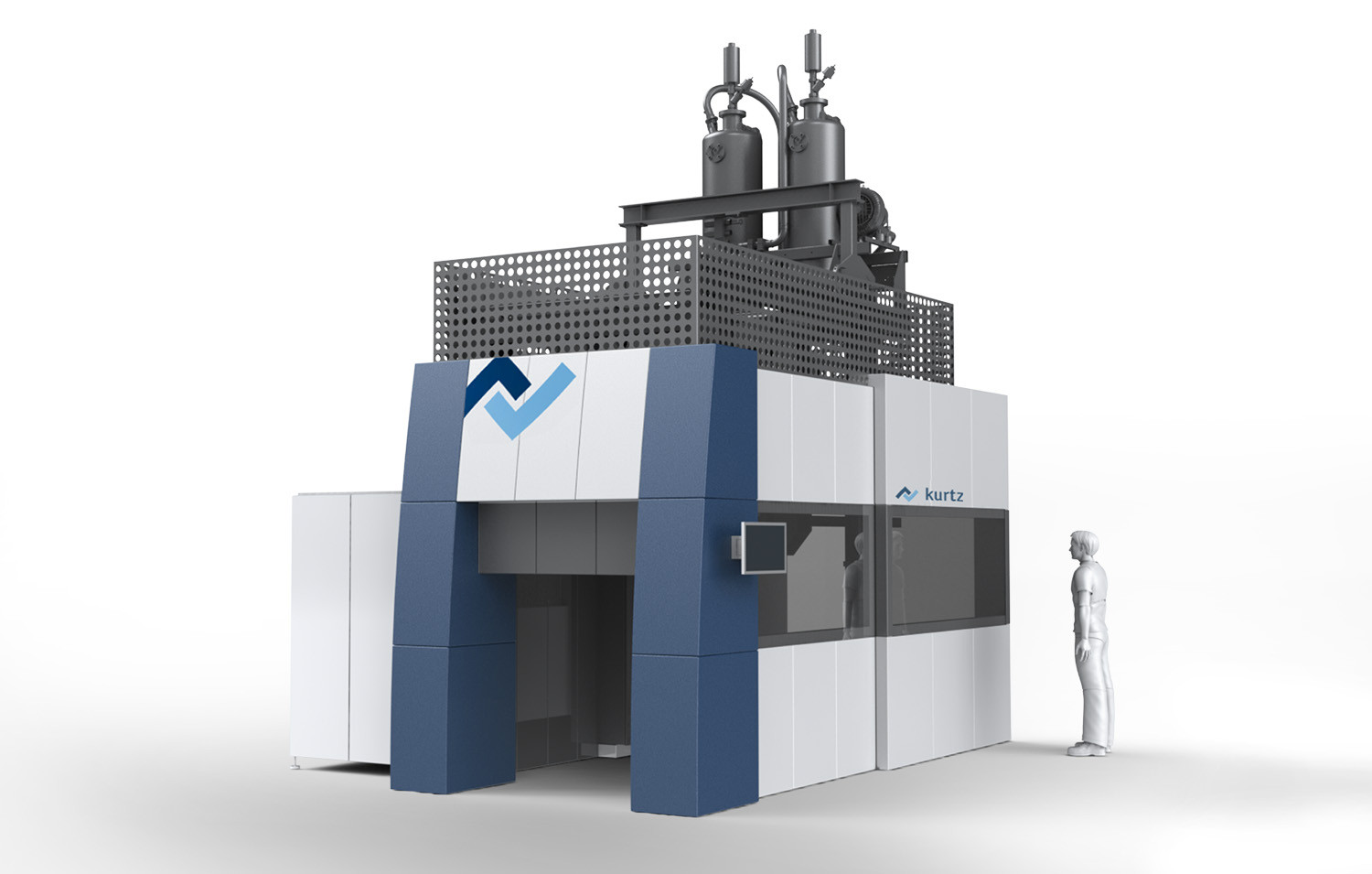

Industrial designers follow a systematic development process that is closely linked to the product development process in engineering. Products are developed iteratively in consultation with customers. Requirements of the target group and the producing company flow into the process. The division into work steps and phases serves as the basis for success through design. This systematic procedure has a long tradition in industrial design.

The design process begins with a design workshop and user surveys. In this way, all requirements are recorded and the goals, orientation and focus of the product are defined. On this basis, designs are created step by step, which are further developed, evaluated, corrected and finally optimised and handed over to construction and production.

All considerations and designs are based on the strategic orientation of the company. Industrial Design supports and develops brand and differentiating features. Products conceived and designed by industrial designers distinguish themselves from similar products with similar technologies and functionalities through an independent appearance that reflects the client's corporate values. This can only be guaranteed by a systematic design process that is interdisciplinary. Employees and expertise of participating departments are involved throughout the design process, which must be aligned with the general product development process in the company.

Sustainable product development

Sustainable industrial design combines ecological, social and economic aspects and incorporates them into the product development process. It analyses the environmental impact of products over their entire life cycle and translates the findings into concrete solutions. It goes beyond purely functional and aesthetic design and also attaches importance to ecological, social and economic aspects.

As little energy as possible should be consumed during the use as well as during the production and disposal of products. Influencing factors that lead to waste and environmental pollution are minimised. Sustainable design takes into account the recyclability of materials and promotes the reuse of products or components. Products are designed to have a long service life and to meet the user's requirements over a longer period of time. Care is also taken to ensure that as few resources as possible are consumed in the production and use of a product.

Sustainable industrial design offers numerous advantages for companies. The ecological footprint is improved for both manufacturers and users of products. Costs can be saved through efficient use of resources. Companies that are committed to sustainability are perceived more positively, can improve their "sustainable" image.

Model Making

Building models is an essential step in the industrial design process. Only through spatial experience can designs be sustainably tested. Models ensure that the planned design draft meets the goals and requirements. In practice, we observe numerous, often vaguely differentiated terms, such as the naming according to project phases (preliminary model, final model and presentation model). Often, media or materials also serve to differentiate (paper model or foam model).

We prefer terms that describe the function and purpose of the model:

A proportion model, for example, provides information about the planned shape, about the size and about the proportions of the later product (synonyms: rough model, preliminary model and volume model). A functional model (synonyms: functional model, effect model or technical model) primarily provides information about the operation and technical function of the product to be expected later. Ergonomics models are used to check the usability. For this purpose, shape, size, proportion and operation are modelled and checked.

A mock-up (synonyms: presentation model, design model and visual model)

is a model that is usually created on a scale of 1:1. It makes products visually and haptically tangible without already integrating purpose or operating functions. For this reason, it is usually made for presentation purposes. You can also say it serves the desired 3-dimensional experience without fulfilling all functions.

Prototypes are 3D design models on a verifiable level. Functions and manufacturing processes are considered, usability and ergonomics can already be tested. Prototypes are often indistinguishable from the final design product and can therefore be used for market surveys and presentation.

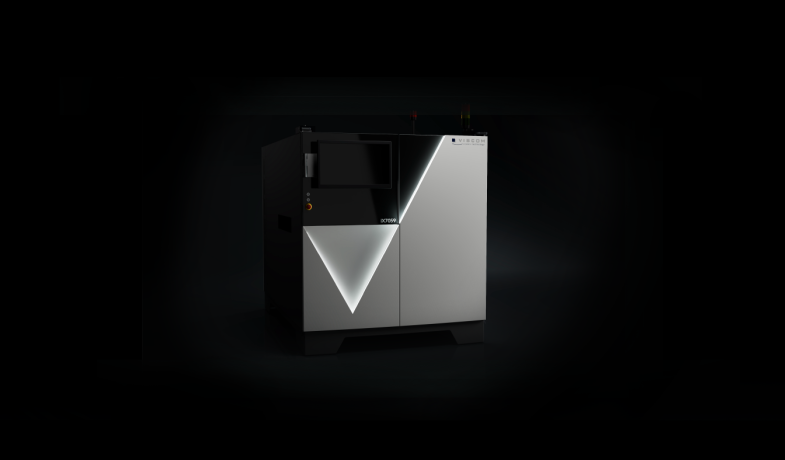

Rapid Manufacturing

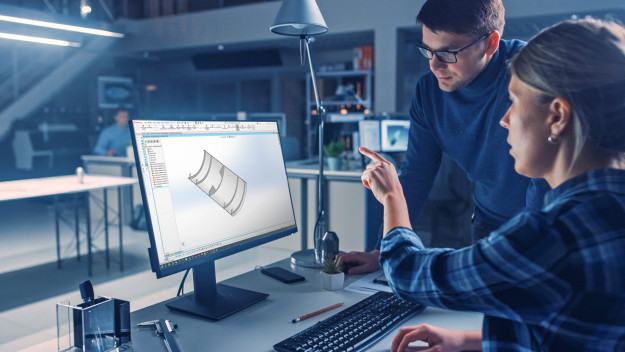

Thanks to this process, customised or individual products can be manufactured quickly and efficiently. Additive or subtractive methods such as 3D printing, CNC machining or injection moulding make the process possible. This is because they allow manufacturing without the use of tools. CAD design data are the basis for products made of a wide variety of materials, such as plastic, metal, composites, ceramics or organic materials. Rapid manufacturing enables the production of highly personalised products that meet the specific requirements of individual customers or market niches. It also makes small batch sizes (quantities) profitable, shortens production times, facilitates product adaptations, reduces inventories and reduces material consumption.

Rapid Prototyping

The term rapid prototyping collects various processes for the production of prototypes or saleable products. The material-specific processes include stereolithography (SL or SLA), fused deposition modelling (FDM) or selective laser sintering (SLS). In this process, 3D data is usually processed using parametric CAD programmes such as SolidWorks, Pro Engineer or Inventor. The process speeds up product development by producing recordable or usable models (see also Design Prototype). This improves communication between stakeholders and teams, reduces development times and speeds up time to market. The result is often higher product quality.