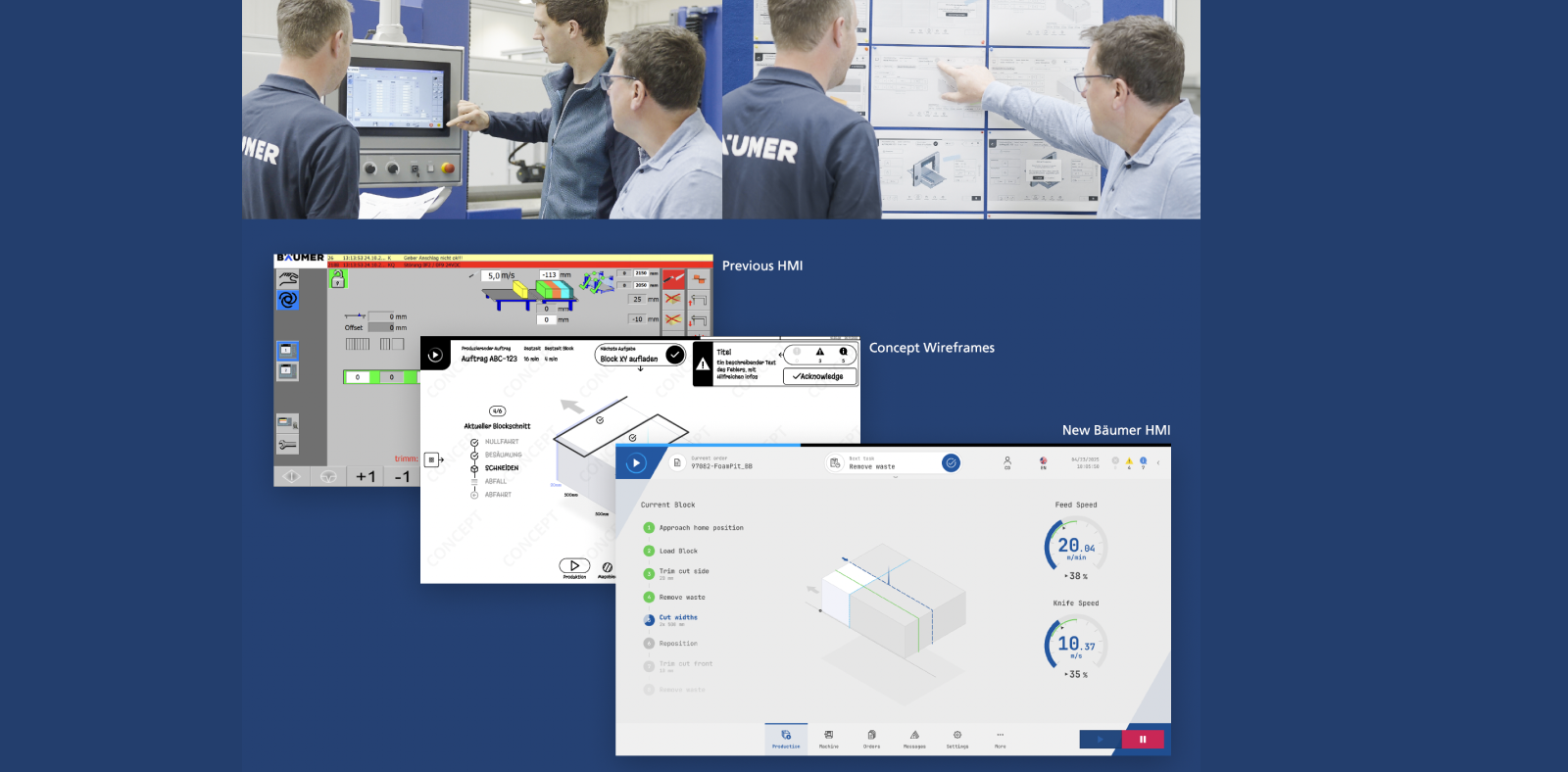

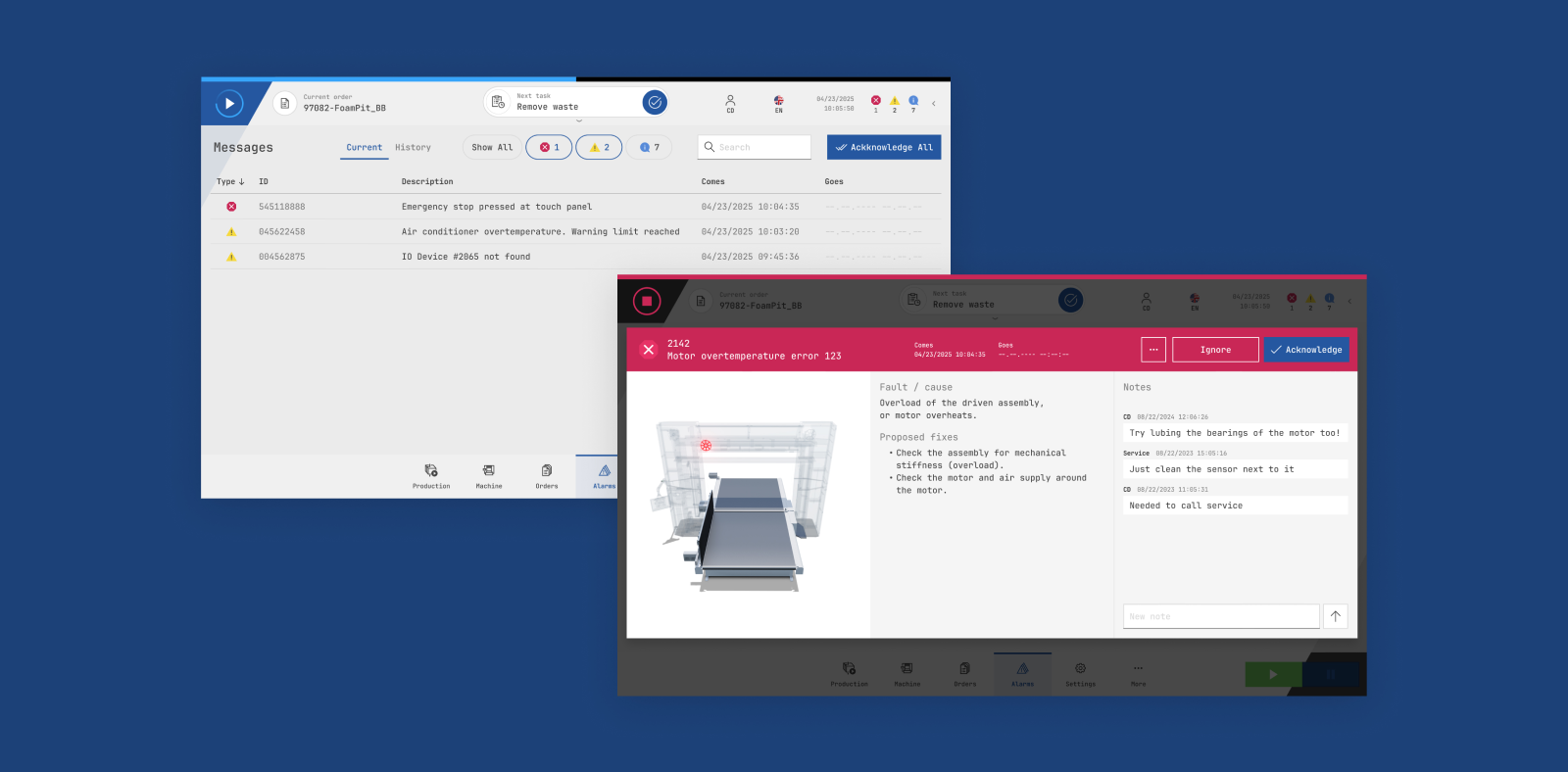

BBS Automation HMI

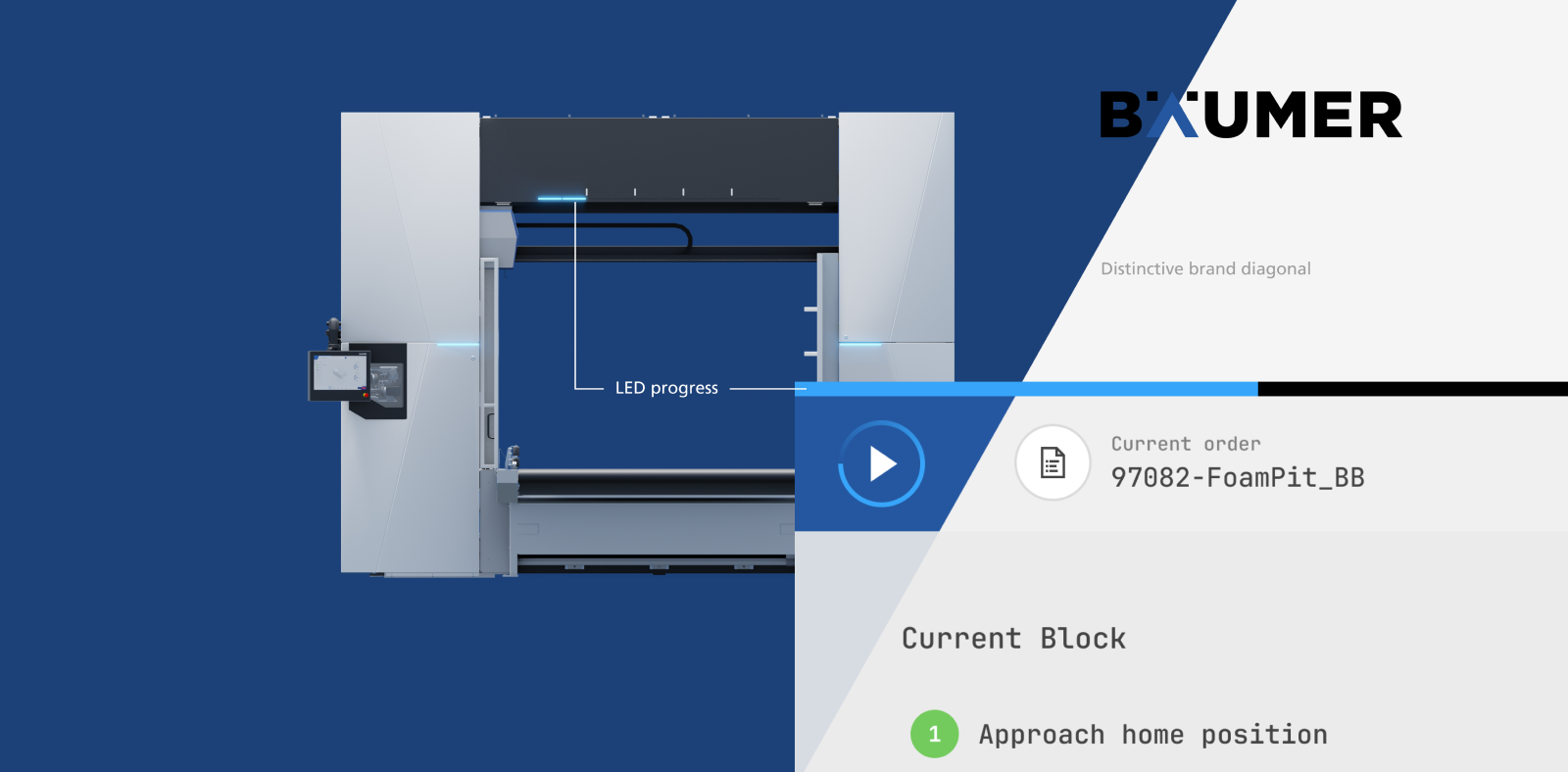

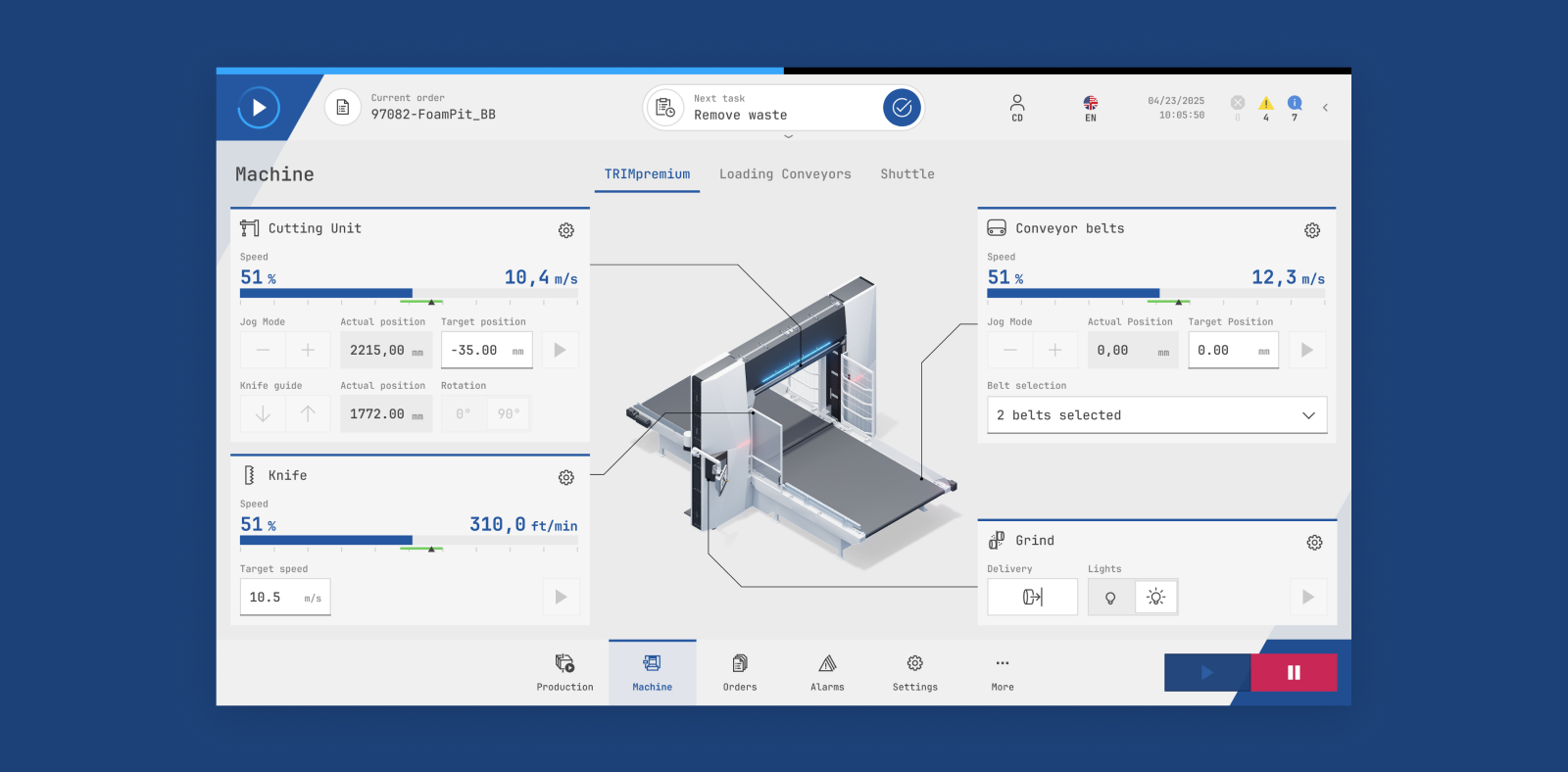

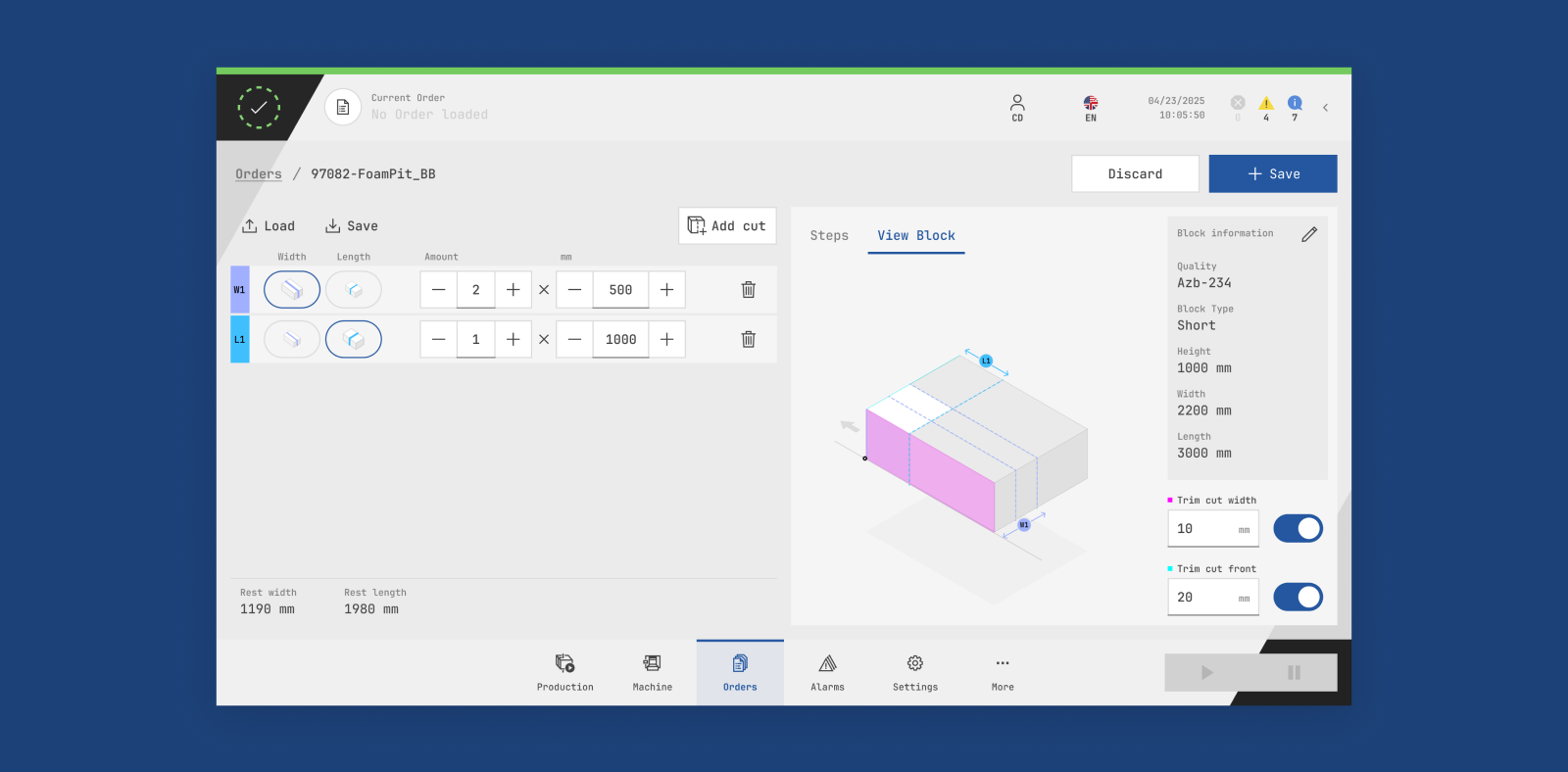

For our client BBS Automation (formerly teamtechnik), a leading provider of automation solutions for e-mobility, medical technology and renewable energy, we developed a modular, user-centred HMI (Human-Machine Interface). The goal: to create a consistent and intuitive interface across different machine types – with clear user guidance, high flexibility and a strong visual identity.