HMI Design and Branding for Nedschroef Machines

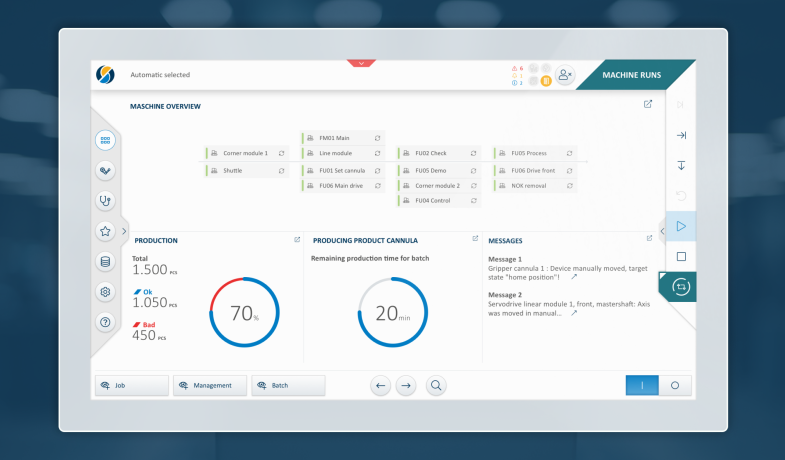

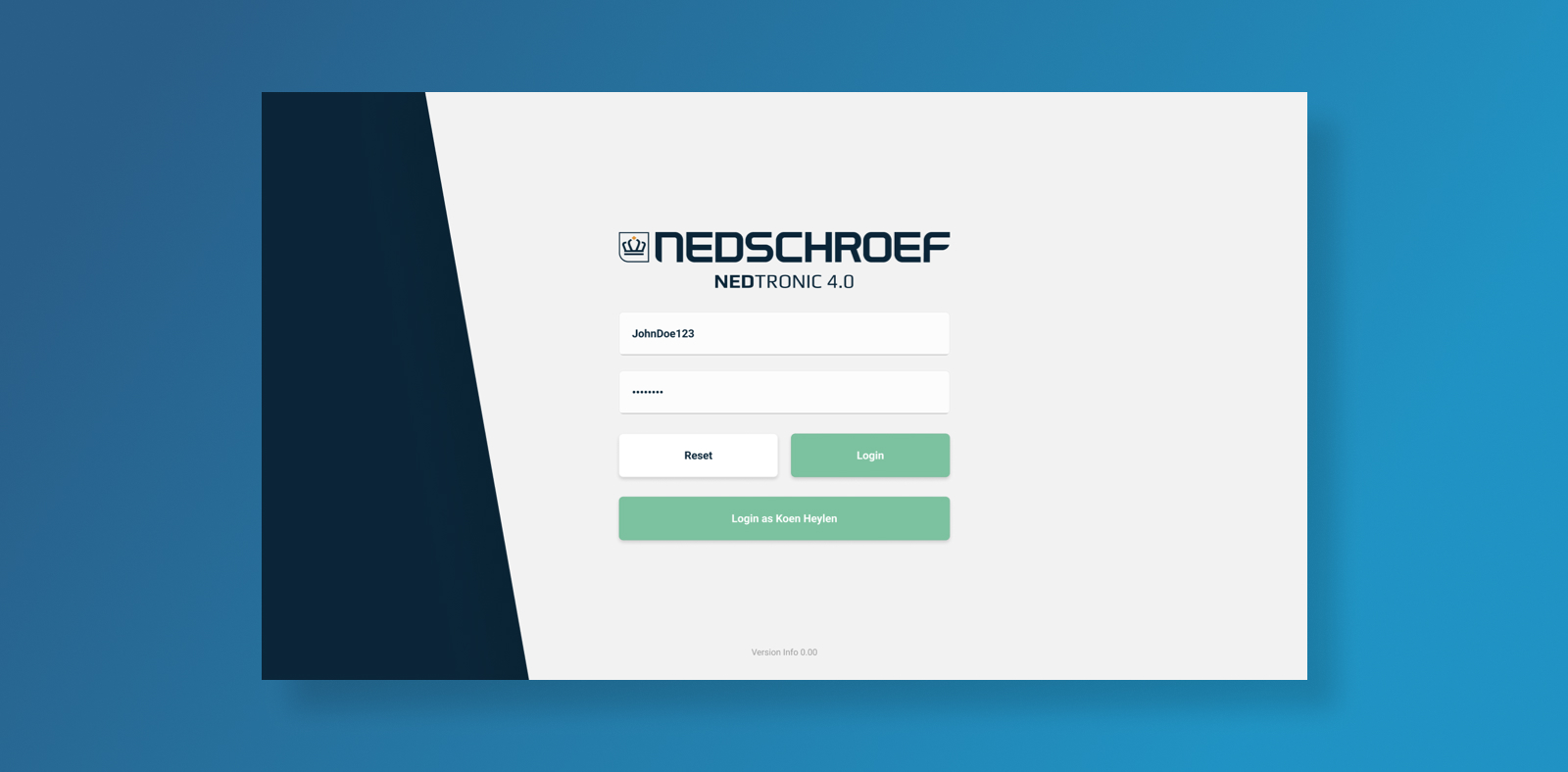

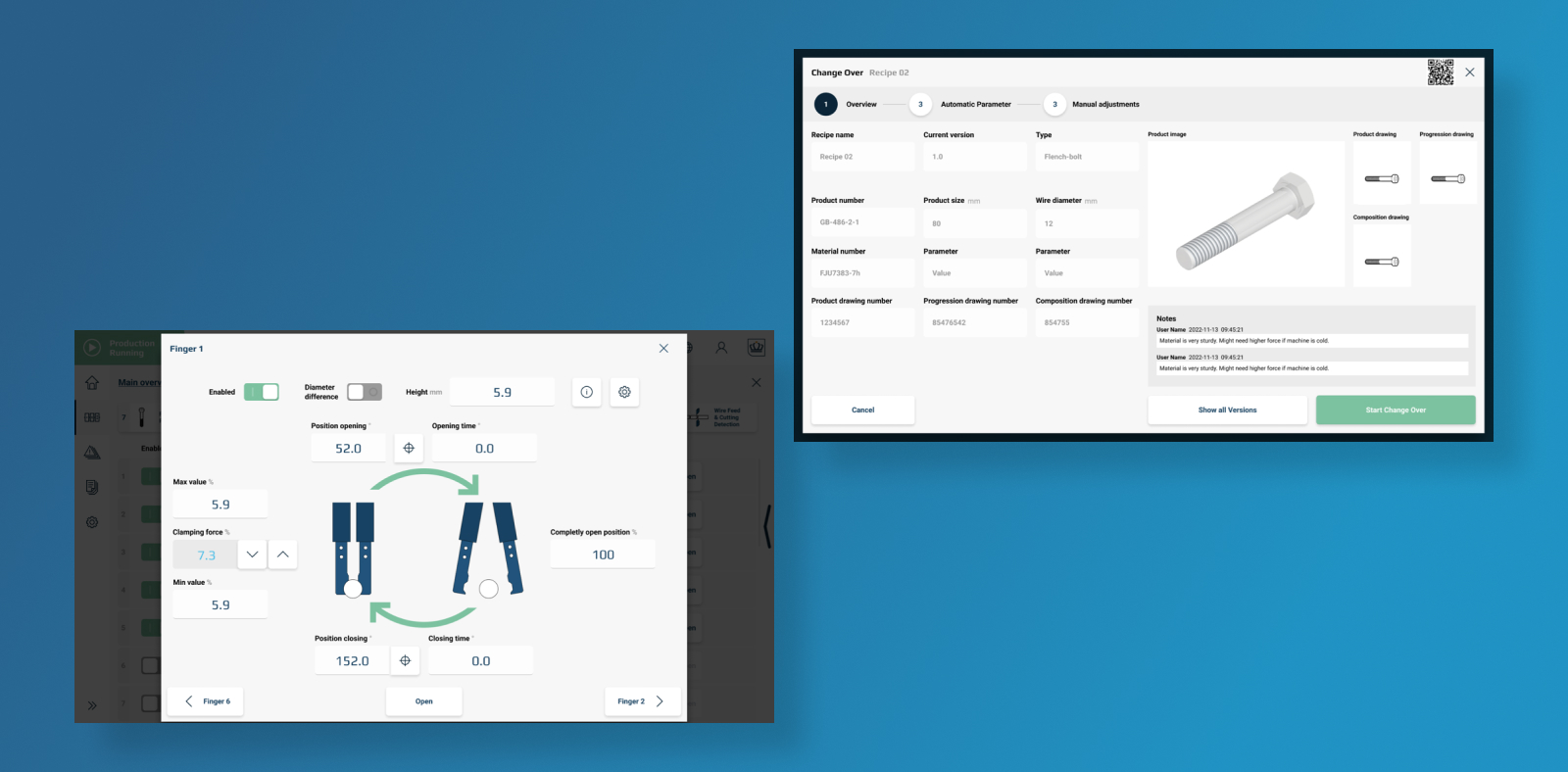

The HMI design is closely linked to the machine branding, reflecting its visual identity throughout the interface. A key design feature is the integration of the machine's slanted lines into the user interface, ensuring a seamless visual consistency.

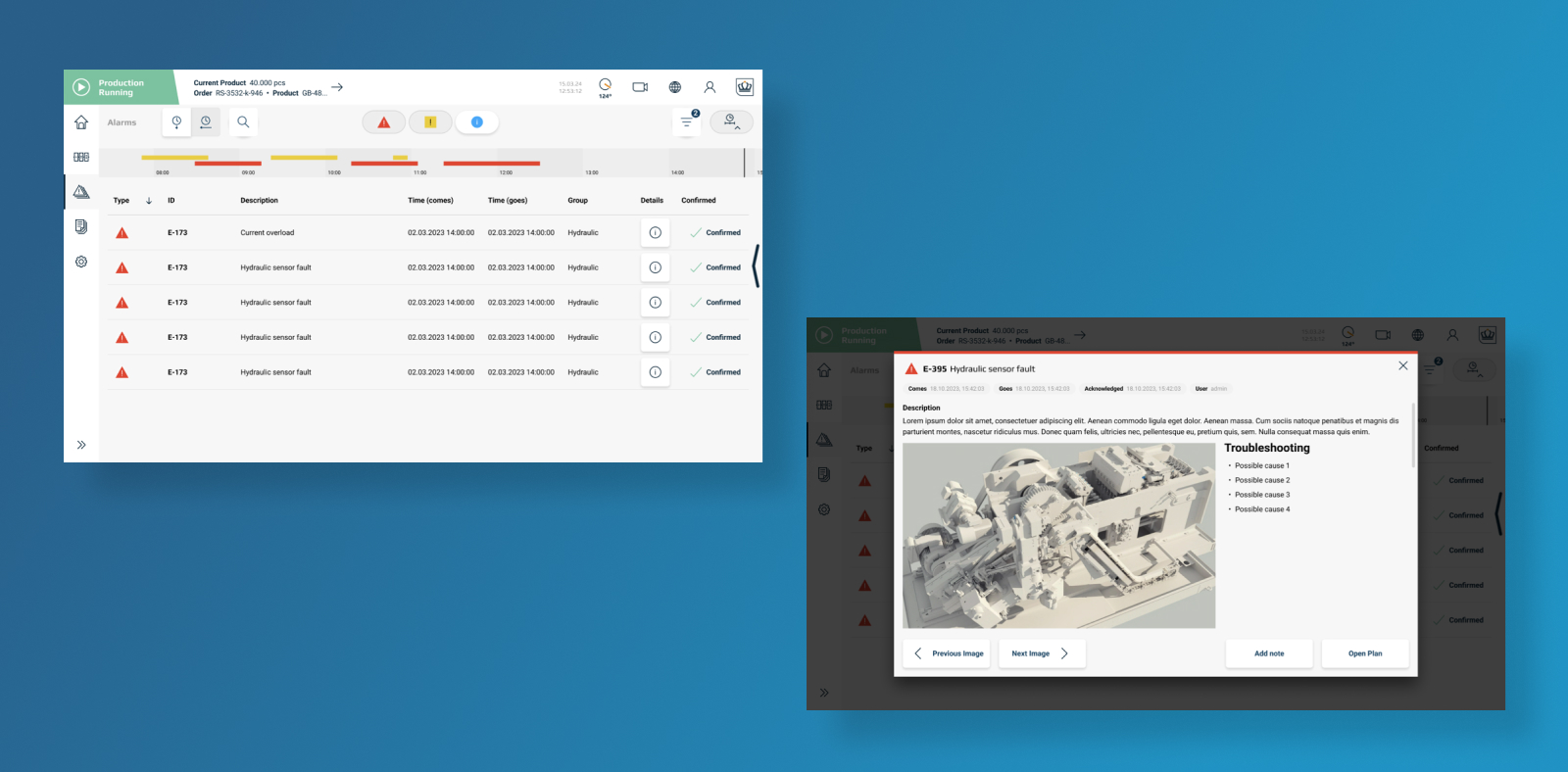

A notable UX feature is the adaptive operator view: the interface remains dark and minimalistic when the machine’s side door is closed and production is running. As soon as the operator interacts with the HMI—such as during error handling—the interface switches to a light mode, simulating the moment the user opens the door and “looks inside the machine.”

This approach demonstrates how thoughtful HMI design can enhance both user experience and the brand identity of industrial machines.