iNDTact smartPREDICT

smartPREDICT monitors the condition of machines and other systems based on vibration measurements. The housing of the smartPREDICT sensor uses a design language that semantically visualizes the topic of sensor technology.

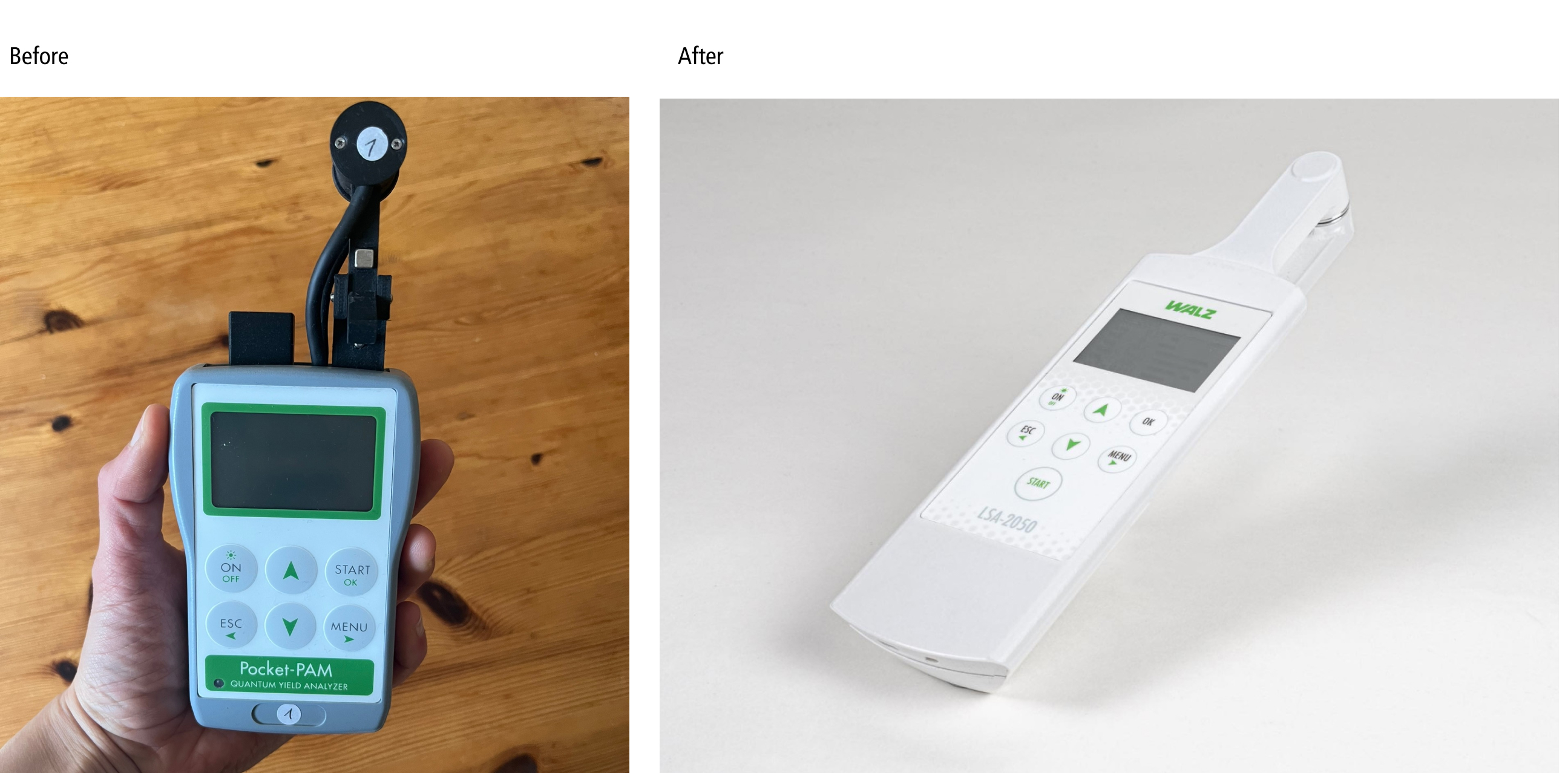

The LSA-2050 LEAF-STATE-ANALYZER is a handheld leaf analyser that works without interfering with the plant. It checks how well the leaves are protected from UV and visible light, measures the amount of green chlorophyll and assesses the health of the plant based on the efficiency of photosynthesis processes. The device shows how well a plant can cope with stress and also records location data and the orientation of the leaves in relation to the sun. We have developed an industrial design for Walz that is ergonomic and light in the hand and can be manufactured using 3D printing and injection moulding.

Special attention was paid to functionality and ergonomics in order to meet the requirements of basic research. The housing of the LSA-2050 consists of two functionally different parts: a clamp for fixing the leaves, to which LEDs and a sensor for analysing the leaves are attached, and an area for handling the device and showing the results on the display. The device can measure not only absorption but also fluorescence, making it versatile, even for non-flat plant parts such as fruit, for example apples. The flexible design enables precise adaptation to different shapes, both with and without a clamp. The housing is ergonomically rounded, making it easy and precise to operate the clamp with minimal effort. A before-and-after comparison shows clear ergonomic advantages and improved handling thanks to optimised leverage. Another decisive advantage of our design is the ergonomic optimisation of the mechanical operation. This can be done comfortably from the home position without having to reposition the hand. The index finger always remains ‘ready for action’ in its resting position, which makes operation even more efficient and comfortable.

Through our work, including the honeycomb pattern in the foil design, we emphasised the core business of the Walz brand and transformed it into a corporate industrial design. The result is biological measuring devices with a clean colour scheme and structured design. The honeycomb structure, inspired by plant cells, emphasises the functionality and purpose of the device. It also creates a smooth transition from lighter to darker areas and gives the device a dynamic and inviting look.

Due to the small number of units, the housing is initially produced using 3D printing. Nevertheless, all components were designed in such a way that they would also be suitable for injection moulding should the quantities change. When creating the design data, particular attention was paid to durability and breaking strength, as well as optimised alignment in the 3D printer to ensure good layer adhesion. The ergonomic design with rounded contours not only facilitates production, but also improves manufacturing precision. Close and cooperative collaboration with the designers was crucial for fine-tuning the components and optimising the manufacturing processes.

The topic of sustainability, improving people's health and well-being, is part of our mission. We are therefore pleased to have worked on a topic that helps to better understand plants, optimise their growth and increase yields through the use of purely organic means. By implementing climate and environmental protection measures and striving for sustainable customers, we endeavour to work for the health and living conditions of all people. As a sustainable company, we want to be a role model.

cadera bei caderadesign punkt de